Higher Education Lab Classes Respond to COVID-19

in Perspectives

by Anna Pravinata, Mamie Harvey, Kristen Salkas, Justin Wilwerding, Teddy Gustafson

This is the second article in a series intended to study the impact of COVID-19 on learning that typically requires in-person, on-site interactions. The first article “Teaching Design Studios during COVID-19” dealt with design studio courses, including architecture, landscape architecture, and interior design.

University education in engineering, manufacturing, and applied technologies typically involves experiments and collaborations conducted in the physical world. Students must handle materials and manipulate equipment. Teamwork is required to operate technologically advanced equipment and manage large lab projects. So how can such topics be taught during a pandemic? When instruction shifts online or classroom experiments must allow for social distancing, how should pedagogy in engineering and related fields change to remain effective?

To understand how college and university faculty have responded to the pandemic and are planning for the fall term and beyond, Alliiance staff interviewed three undergraduate instructors, one maker-space manager, and one graduate-level teaching/research faculty member. Our interviews with these educators shed light on a variety of teaching challenges related to COVID-19. In the hope of helping other college and university instructors as they prepare for the uncertainties of teaching this fall, we have decided to share the key observations and takeaways gathered from our interviews.

ADJUSTING TO THE SHIFT

The educators we interviewed worked hard to switch to remote teaching within a matter of days last spring. Their students were mostly understanding and flexible in accommodating the new remote context. But while technologies like Zoom, Canvas, YouTube, and Google Docs helped bridge the abrupt shift to online work and communication, nearly everyone agreed that virtual interactions were generally a poor substitute for those that occur in the physical classroom, where collaborative problem-solving enhances the overall learning experience.

Nonetheless, the instructors who participated in our interviews said they expected to make an online version of their course available to students in the fall. They intended to use the experiences they acquired last spring to shape their curriculums, tailoring the overall approach and assignments to fit the parameters of COVID-era learning.

To address the orientation to physical materials shared among these disciplines, several common strategies emerged. Among them:

- Remotely viewed demonstrations – Using Zoom or other video-chat software to conduct demonstrations of scientific tests or technological procedures.

- Individualized exercises, experiments, or practicums – The distribution of experiment kits and inexpensive data collection devices to allow students to conduct trials and experiments from their homes.

- Proxy production and prototyping – The use of email or file transfer websites to deliver electronic model files to the maker-lab, which instructors and teaching assistants can then upload to a 3D printer or other production equipment (CNC machines, etc.); finished products can then be mailed or positioned for curbside pick-up.

- Pre-scheduled access to high tech equipment – The use of web-based platforms that allow students to schedule a time when they can individually use on-site high-tech equipment housed in laboratories.

HANDLING EXPERIMENTS

William Northrop, Associate Professor and Director of Undergraduate Studies, Mechanical Engineering, University of Minnesota, plans to adopt a multifaceted approach. Lab experiments will be conducted by teaching assistants and broadcast via Zoom. Students can ask questions via the Q&A or chat features of Zoom as the TAs conduct the experiments.

Northrop is also exploring the idea of “Take Home Labs,” providing students with simple kits that include materials and perhaps even low-cost equipment for conducting individual experiments for his Energy Conversions class. In some ways, individual research experiments are superior to group research because each individual is responsible for understanding and executing every step of the project. Students will learn more when they must do the whole experiment solo and as a result, hands-on skills and learning may improve.

If a class requires on-site learning, students will schedule appointments for visiting the designated facilities and cleaning will be done in-between. Post COVID-19, each science teaching lab will need to be equipped with robust AV systems for recording and broadcasting as well as good acoustics.

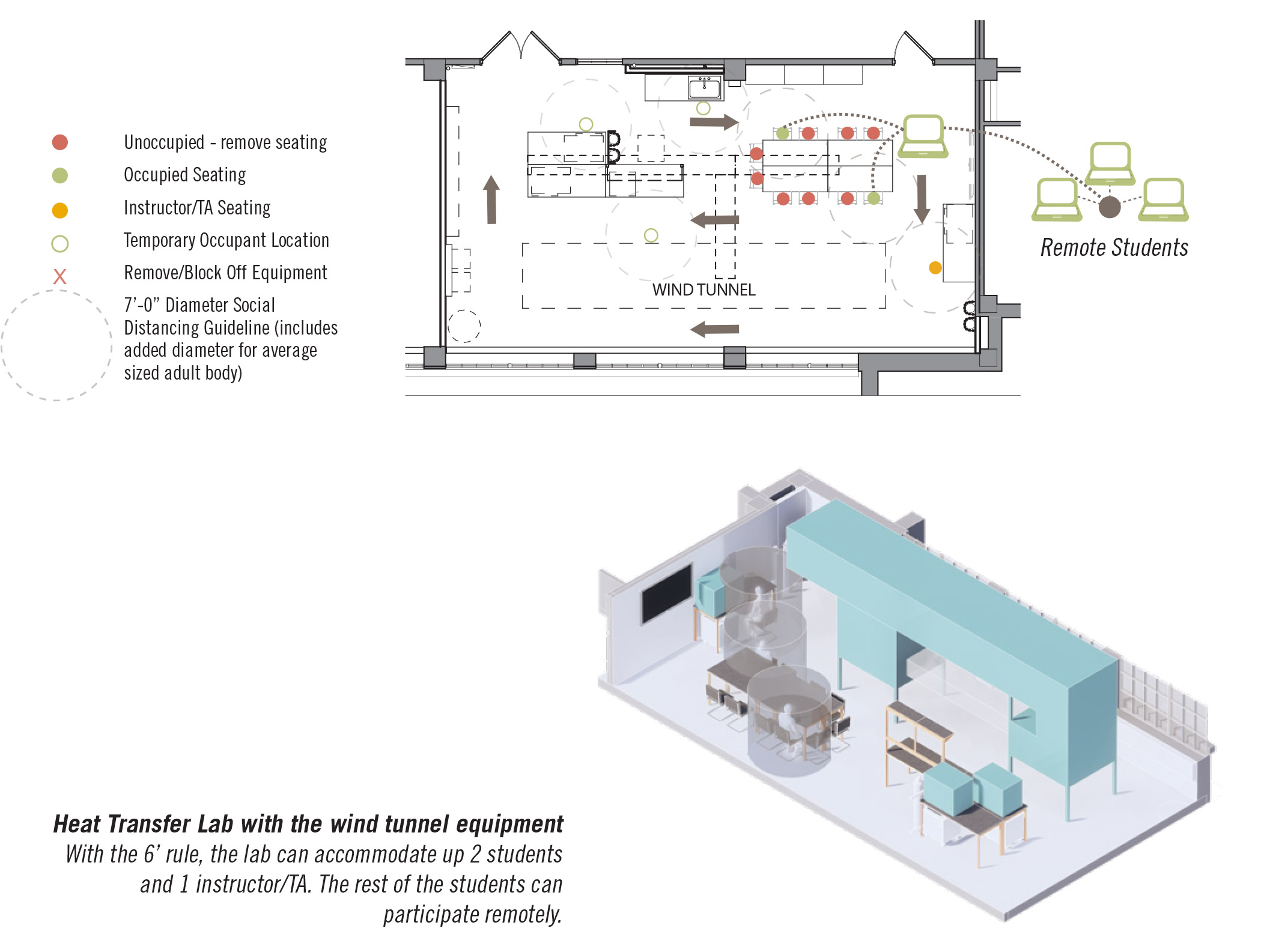

One of the teaching labs at the University of Minnesota is the Heat Transfer lab. Alliiance simulated how many students can reasonably fit in this lab with the social distancing restrictions and where to potentially install AV equipment.

MAXIMIZING OFF-CAMPUS EXPERIENCES

Last spring, Olle Gladso, Automotive Service Technology Instructor, Riverland Community College, took advantage of the fact that each of his students had an internship in an auto shop, which were essential businesses, so they stayed open. To teach students, Gladso created a short video around each learning concept and shared it online. He then asked students to apply the concept at the internship site and record the procedure as evidence they understood the lesson.

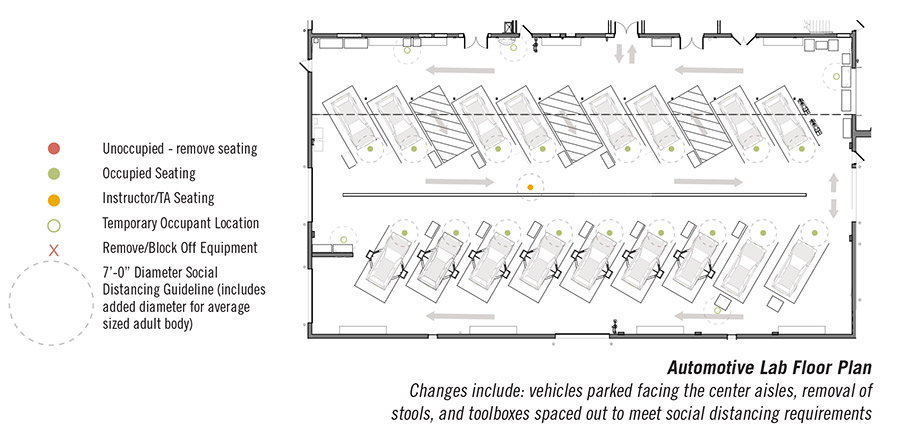

Students are attracted to Riverland’s programs because of their hands-on approach. Fortunately, the community college has large labs that can accommodate social distancing, and Gladso expects the college to open to students in the fall. Cleaning and sanitizing protocols will be put in place, and the configuration of vehicles within Gladso’s classrooms will have to be altered to allow instructors to check work and consult with students at a distance. Still, to comply with CDC distancing guidelines, instructors may need to use cameras or other technologies to view some student work.

EMBRACING DIGITAL LEARNING

Kent Kirkby, Teaching Professor, Earth Sciences, University of Minnesota, will only offer online instruction this fall. But he plans to introduce more online tools, like Google Earth, to aid in student learning. All materials for labs will be digitized, including PDFs of maps and 3D scans of skulls for ease of student access. The department will continue to teach asynchronously to allow international students with time differences to join in their time zone.

The input of students from the spring term has also prompted faculty to streamline student assessments. One of the challenges experienced by students during the pandemic is the wide variability in highspeed internet connections across the country. This can be particularly problematic for students taking timed, online quizzes or trying to complete hours-long labs, so Earth Sciences faculty have begun sending labs in an Excel form, which allows students to download the lab, complete it offline, and upload the Excel file back to the online course page.

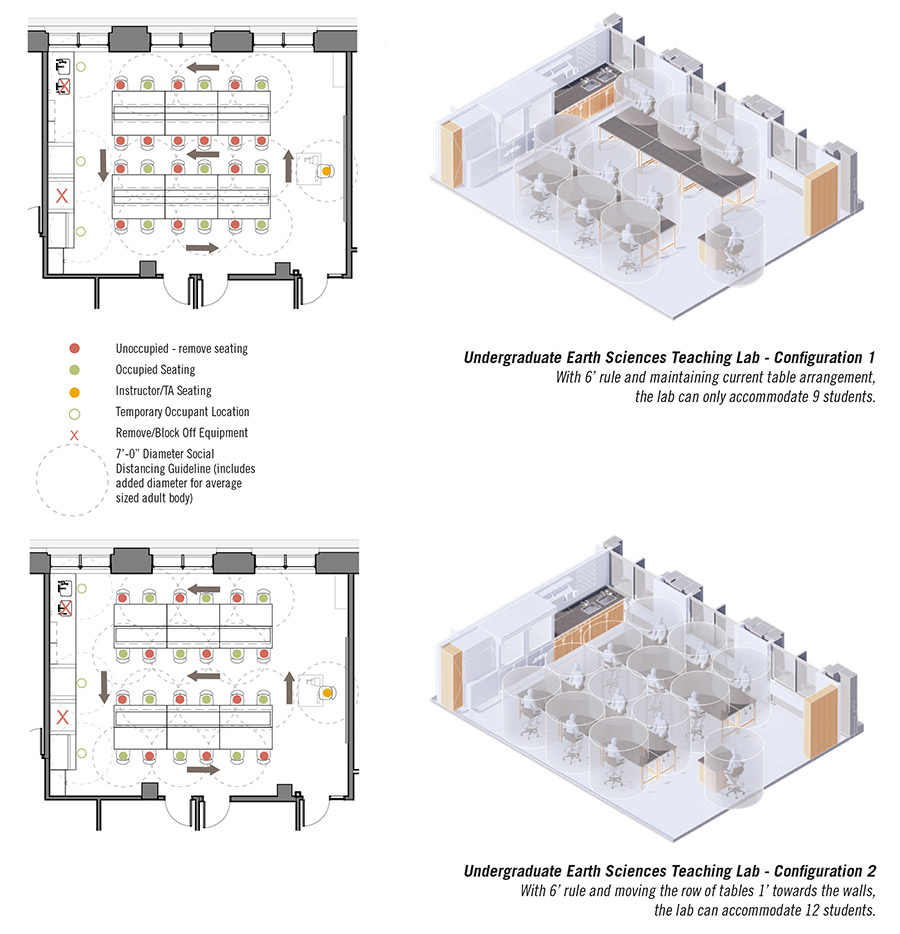

As long as the social distancing requirements remain in place, Kirkby says, there is not sufficient space to allow enough students in each lab to make the on-site learning efficient and effective. To ensure that collaborative learning is effective, about 50% of the class (12-14 students) need to be present. Current laboratory layouts will only allow for a social distance at about 3’-4’ for 12 to 14 students which are not aligned with current CDC guidelines. Alliiance simulated a couple of configurations for one of the Earth Sciences teaching labs.

SCHEDULING EXPERIMENTATION

After Minnesota’s governor issued a stay-at-home order last spring, the University of Minnesota immediately closed its makerspaces and shops. According to Ben Guengenrich, Manager of Anderson Student Innovation Labs, University of Minnesota, prototyping requirements were dropped from classes and design became the primary focus. In early May, the makerspace and shops were opened to allow for COVID-19 research, such as developing and making masks—but not other student uses.

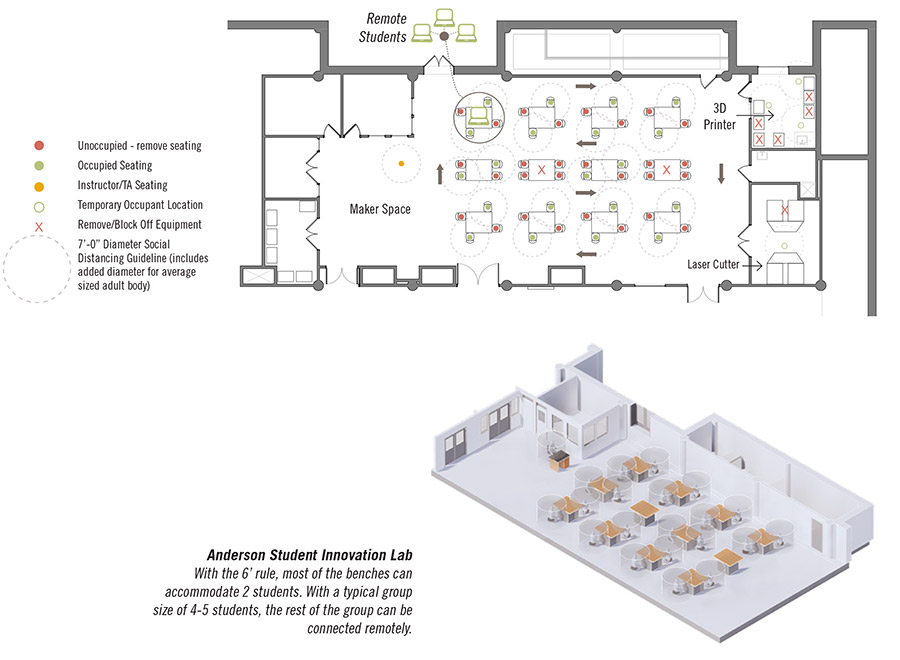

Plans for the use of the Anderson Student Innovation Labs in the fall, developed by Guengenrich offer several ways to support the prototyping effort: First, pre-scheduled time slots will be arranged for students to conduct lab-work. This provides an opportunity for students to develop specific skills supporting their “making” work in the labs. Second, the maker space will leverage a “service bureau” model, whereby students send their designs electronically to staff in the innovation labs and plans are transferred to computer-driven equipment for prototyping. Lastly, group project design work will be executed entirely in a virtual format. Prototyping projects can be developed through a combination of on-site and virtual collaboration; e.g. two students employing on-site equipment in the maker lab to build the prototype, and three partners using Facetime/Zoom to watch the production of the prototypes and discussing the prototype process.

COORDINATING COURSEWORK

Last spring when COVID-19 hit, Professor Muhammad Shah Jahan, Ph.D., Department of Physics and Materials Science, at the University of Memphis, stated that the professor-in-charge of all instructional labs was charged with coordinating all the science lab instructors. The same professor-in-charge assisted TAs and teaching instructors in readying and adjusting the curriculum to address the remote learning effort necessitated by the pandemic. The work was shaped by a set of stringent guidelines that had been developed by the University of Memphis. Professor Jahan commented that while these guidelines are very complete, they are also a work-in-progress due to the evolving nature of the virus.

The nature of research in Physics and Materials Science has made the shift to remote learning somewhat easier since students are used to working on a round-the-clock schedule. This tends to ease the demand for time in the physical lab spaces, spreading their use over a longer period and facilitating a reduced number of students in spaces at one time. Since the work of material science requires students to use physical lab spaces, the university and the Physics and Materials Science faculty carefully monitor who is accessing lab spaces at all times through access card technology. This means that the number of students in each space can be carefully managed to diminish the prospect of spreading the virus.

The changes in curriculum delivery at the university and within the Department of Physics and Materials Science have been carefully shaped by the CDC guidelines and university safety protocols developed in response to COVID-19. For most of the graduate research classes, Professor Jahan stated instructors and student research teams meet in the research labs one-on-one observing social distancing guidelines, or via Zoom. Further, students and faculty are required to wear masks at all times in all spaces. But Dr. Jahan also commented that there has been some negative impact on student outcomes as a function of the on-going concerns of students who are obliged by the need to utilize physical lab spaces for experimental purposes.

The interview process prompted faculty to both reflect on the spring term and look forward to the fall term and beyond. Their thoughts pointed to a range of possible changes that will be required in science instruction post COVID-19:

1. Science teaching labs will need to incorporate robust AV and good acoustics to allow for good quality broadcasting and recording.

2. All lectures should be recorded and shared online. This will both accommodate students learning in distance format who reside in differing time zones and enable students to watch the lecture multiple times to get a better understanding of the subject matter.

3. Some disciplines will continue to use readily available online tools to expand the curriculum, for example, using Google Earth to analyze Mississippi River management schemes.

4. Makerspaces will continue to offer the “service bureau model” for faculty or students who just want “parts” and are not wanting to learn how to use the equipment.

5. Even though online learning can replace elements of the learning experiences in science, engineering, manufacturing, and applied technologies, some of the aspects of on-site learning cannot be replaced including:

- Collaborative interactions between students and students and instructors.

- Elements of the college experience entailing collaboration with a more diverse population of people, and the new learning situations that emerge from these encounters.

- Tactile, hands-on experiential learning situations that engage multi-sensory learning such as touching dinosaur eggs, smelling diesel fumes, and operating a wind tunnel.

We believe the evolving nature of the pandemic will continue to spawn new insights and approaches to teaching and learning science. Not every challenge can be addressed with technology or space changes, but we remain confident that smart educators and innovative designers can collaborate in ways that ultimately benefit students. With effort, the learning that happens in the fall and beyond can be stronger and more effective than it was even pre-COVID-19.

We would like to thank our contributors:

- William Northrop – Associate Professor and Director of Undergraduate Studies, Mechanical Engineering, University of Minnesota

- Olle Gladso – Automotive Service Technology Instructor, Riverland Community College

- Kent Kirkby – Teaching Professor, Earth Sciences, University of Minnesota

- Ben Guengenrich – Manager of Anderson Student Innovation Labs, University of Minnesota

- Muhammad Shah Jahan, Ph. D. – Professor, Department of Physics and Materials Science, University of Memphis